KCE RETURNS FOR MORE

There has been a long relationship stretching back many years between the KCE Group of Thailand and PAL. Six PAL lines have been installed in the original KCE factory, and four in the second factory – KCE International – in the 1980s and early 1990s. Therefore, when KCE built a new factory – KCE Technology - outside Bangkok at the turn of the century it was no surprise that they should turn to PAL for four plating machines – a Pattern line, Desmear/PTH line, Electroless Nickel and Gold line and a full depth Tab Plater. Now they have ordered a second Pattern line from PAL for this plant.

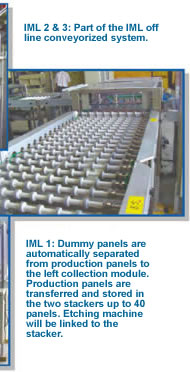

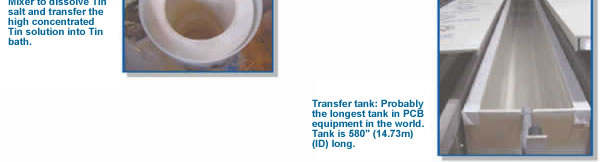

“The new line for KCET is a huge machine in an H shape,” explains Kelvin Lau of PAL. “It is separated into two phases with a long transfer tank forming the link between the two phases and creating the ‘H’. Output capacity is 5,000 panels a day for the first phase and this will double once phase two is installed. Phase I was delivered at the end of June this year, installation started at the beginning of July and the machine was commissioned at the beginning of September. KCET would like to have Phase II completed in February 2003, which means that delivery will be in December 2002.” Each arm of the new line is 40m long and 7m wide with 15 copper plating tanks for the first phase and 13 for the second, and has three sets of transporters for phase one and four for phase two. With semi-automatic load and fully automated unload using an IML conveyor system effecting a direct link to the etching machine. The new line features many of PAL’s latest state-of-the-art technology including their Eductor system, ORS, ‘Aero Wing’ shielding system and mixing chamber for Tin plating salts, and maintenance and make up chemistries. More on the KCE Group at www.kce-hq.com

|

||||||||||