FILTRONIC ORDER PAL LINE + WASTE WATER TREATMENT PLANT FOR NEW CHINA FACTORY

Filtronic, the world leader in the design and manufacture of a broad range of customised RF, microwave and millimetre wave cellular and broadband components and subsystems has ordered a plating line from PAL for their factory in Suzhou near Shanghai, China. Installation of the new PAL line, a manual Silver plating machine for RF components, featuring purpose designed agitation on the Silver and electroless Nickel baths; ultrasonic cleaning; jig stripping facilities and an airless (eductor) solution agitation on Nickel and Silver plate, took place at Filtronic (Suzhou) Telecommunication Products Co Ltd from mid-March and the line has been in full production since June.

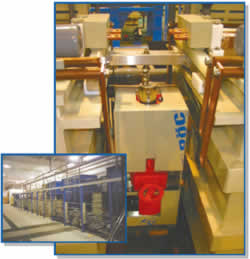

Filtronic also ordered a waste water treatment plant from PAL, featuring amongst other attributes:- automatic monitoring of final discharged water; closed loop management of all cyanide rinses and RenoCell reclaim of Silver metal. In collaboration with a specialised design institute PAL was able to work with Filtronic on the application for government permits for the factory. Buy off of both the machine and the waste water plant was completed successfully in early February with shipment taking place at the end of the month to avoid the Chinese New Year rush in the middle of the month. The Filtronic (Suzhou) operation was formed in October 1999 to support the rapidly expanding telecommunications market in China, and to provide a local source of products for the cellular handset and wireless infrastructure markets. The company originally operated from a purpose built facility in the Suzhou New District Hi-Tech Industrial Park with a total area of 2,400m2. Increasing demand for wireless products in China resulted in Filtronic (Suzhou) opening a second larger (5,800m2) factory in September last year. With future growth in mind, the option for an additional 2,500m2 of production area was incorporated into the design of this building. The construction of the 2,400m2 Silver plating facility completes this stage of the development of the Suzhou site. “The selection of PAL to design and manufacture our new plating line and waste water treatment plant was based on many months of research and discussion,” explains Project Manager Alistair Barr, of Filtronic. “We were well aware of PAL’s international reputation for innovative design, the quality of plating produced by their machines and their long-term customer support. In our meetings with them, we very quickly realised that we were entering into a partnership in which they took on board all our requirements and rose to the challenge of producing equipment designed specifically to meet all our objectives.” “PAL’s knowledge and experience of Western and Chinese standards and practices obviously stands us in very good stead as, just like them, we will be manufacturing in China for the international market,” stated Andrew Wilde, Filtronic’s Technical Manager, adding that “knowledge of Chinese regulations was obviously of particular importance as far as the waste water plant was concerned.” “We were delighted to receive this order,” said PAL’s Managing Director, Geoff Paterson. “It encompasses so many of our interests. Internally we count this as a GMF line because of the process for which it is to be used, yet it is for a company serving the electronics industry, just like us. Filtronic’s order for a wastewater treatment plant emphasises the growing importance of ensuring that the environment is adequately protected. We are seeing an ever-increasing number of “with-WWT-plant” orders from all over the world. Ours is very much a ‘complete solution’ for Filtronic including a water treatment facility designed to generate the good quality deionized water required for plating, a plating line that deposits a Silver layer on to the product, a waste water treatment plant that handles the waste water and also a fume scrubbing facility to handle the discharged air from the plating line.” Superb after-sales service for customers in China WWT with an added bonus “There is increasing awareness of the importance of environmental protection in China and we believe that this waste water treatment plant will help Filtronic meet all current and perceived future requirements. This project has given the PAL-ED (PAL Environment Department) team valuable experience that stands us in good stead for future projects in the north east of China,” adds Geoff Paterson. Information on Filtronic can be found at www.filtronic.com

|

||||||||