PAL MAKES NEWS AT RUWELIt was in June 2002 that PAL celebrated their first order for a plating line from Germany for some time and that the machine ordered by RUWEL would be a record breaker as it was destined, at 5.75m, to be the widest ever made by PAL. The record-breaking line incorporating defining technologies such as pulse plating, Eductors, OSSTjWin and fully automatic load and unload stations. It was to be in production by the first quarter of 2003 (see PAL News, Autumn 2002).

An article by Graham Benton of PAL Europe in "RUWEL Journal" (Issue No. 6) tells the complete tale and includes interesting photographs relating to plating quality. Copies are available in either English or German from PALís marketing department in Hong Kong or from PAL Europe in the UK. In it Graham explains the background to the order and the various stages from that moment on...... Naturally he looks at the vital issue of plating performance and quality: "The all-important copper plating stations are equipped with the latest PAL innovations such as submerged Ti-clad anode rails, PAL floating shield system, and anode compartments with PP diaphragms," he writes. "Particular attention has been given to the auto-dosing and vibration systems enabling precise, accurate and repeatable electro-chemical performance to be maintained at all times. The plating performance is further enhanced by the use of reverse pulse rectifiers, and airless eductor-based solution flow systems. The choice of these technologies and PAL proprietary design features such as angled agitation integrated on the plating line, allow tightly controlled plating performance. This was amply demonstrated during the line commissioning phase, when the plated results beat PALís guaranteed 8 % CoV by a large margin! Tests undertaken at that time for one of RUWELís major customers showed the quality of plating that can be expected, and constantly achieved by the machine."

PAL is hard at work building a second machine for RUWEL. This one, scheduled for delivery during May, is a Compal Electroless Nickel/Gold line with two transporters capable of taking a dozen panels, typically measuring 640mm x 538mm, in each basket load; and of plating a thousand or more panels each day. "We were impressed by the great cooperation there was between PAL and RUWEL when our earlier machine was built," explains Ad van der Kruijs, Member of the Executive Board of RUWEL, responsible for technology. "This, combined with the quality of the machine that measured up to all our expectations and their flexible and creative on-site team, meant that as far as we were concerned, the design for our new Ni/Au line was indeed an offer we just couldn't refuse!" The OSSTjWin fixed cycle program and data-monitoring software in its German version lies at the heart of the 23-stage machine enabling RUWEL to plate mixed loads - PAL can now supply OSSTjWin in seven languages. Other features include an air blower and in-line dryer, vibrators on the flight bars and solution trays under both the Gold tank and the overall structure. These trays are an essential aid for ease of cleaning.

Further information on RUWEL from www.ruwel.de

|

|||

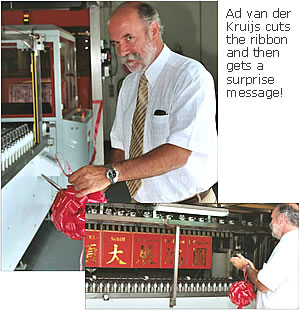

There

were great celebrations when the machine was officially handed over

?Chinese firecrackers, Chinese food and a very special message

delivered to Ad van der Kruijs, Member of the Executive Board at

RUWEL via panels on the machine!

There

were great celebrations when the machine was officially handed over

?Chinese firecrackers, Chinese food and a very special message

delivered to Ad van der Kruijs, Member of the Executive Board at

RUWEL via panels on the machine!