OSSTjWin: NEW VERSION AVAILABLE

PALCON in Malaysia, the development centre for the

OSSTjWin, PAL’s widely used ordering and monitoring

system, has now been in operation for more than three

years.

The development team has been working hard to release

new versions. Besides minor features, the next version

released this September, contains the following major

features:

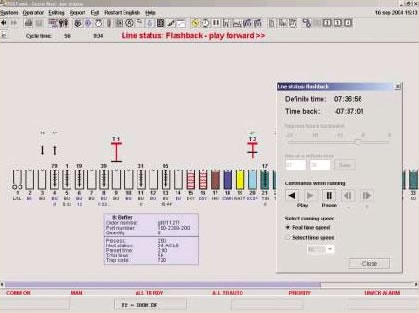

- Flashback

This is a very powerful tool enabling the user to re-play the

past 24 hours, in real time or in a higher speed format. All

transporter movements and flightbar locations, with their data,

can be monitored, using the same function that is normally used

during production. The user can explore it like a video/DVD

player and pause, play step-by-step forward/backward with the

selected speed, play forward/ backward in real time or at a

higher, selectable speed. The user can easily search for a certain

time of the day or just move a time ‘slide bar?to the required

time slot.

The advantage of this function is to find the cause of all

sorts of problems, such as when:

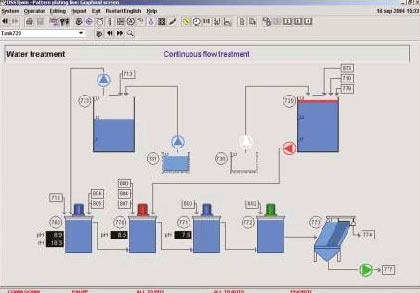

- A built-in basic MMI (Man Machine Interface)

This is like a stand-alone software package, fully integrated

in the OSSTjWin. There are two different purposes of this function:

The normal purpose is to customise the screens with the equipment

around the tanks, like filter pumps and sump tanks with their

pumps and valves. The second purpose is, if there is a small

or medium sized waste water treatment for the line, it could

be included in the same control system with obvious cost saving.

Those screens can be designed by PAL engineers, or even by

the customers themselves. There is a basic, but powerful, built-in

editor to design the screens. There are standard symbols like

tanks, pumps, valves etc., where each object can have an associated

"tag" to indicate its status (volume for tanks, different colours

for off/on/alarm status on other objects). Each object can have

a "link screen", when, by clicking on the object, the other

screen is displayed. The users can also create their own symbols,

which can change shape depending on the status of the "tag"

variable

Besides the advantages of customising the screens for the line,

the advantages of this function, when used for a waste water

treatment are:

- Side Equipment Function

This function will collect standard side equipment instruments

for each station and display them on a separate screen. By clicking

on a tank, all associated instruments for this tank like temperature

meters, rectifier meters, switches etc., will be displayed.

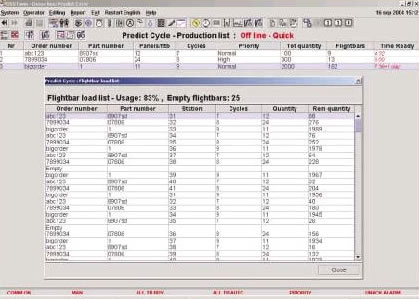

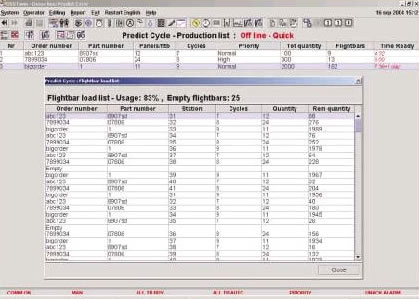

- Predict Cycle Scheduler

This new scheduler is based on a fixed cycle (a time/way diagram).

The fixed cycle ensures a high output but with some limitations

in mixing different products. Even though, in a sub-cycle (e.g.

zinc), the time can be individually set on any multiple of cycle

time. For example, if the cycle time is 6 minutes, the zinc

plating time could be set to 6, 12, 18, 24, etc., minutes.

The "Predictive" part is that the user can enter the production

list for the day, select priority for the different orders to

be run, and finally select "Optimise". The system will optimise

the usage of the line in the best way, trying to keep the sub-cycle

(e.g. zinc) as much used as possible, with its different plating

times. The user will also get the information about when each

order will be finished!

Another feature is that the user can enter the production list

for next day, just to see when the different orders will be

finished. And when running with any particular production list,

the user can try to re-optimise it, changing priorities and/or

adding other orders to the production list, to see the impact.

Then the user can select "Go" or cancel this new production

list optimisation.

Example of the Predictive Cycle function

|