OSSTjwin FOR PAL LINE IN ISRAEL

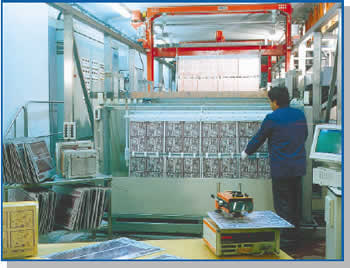

It’s the step that Israel-based PCB Technologies Ltd has just taken. Their PAL Pattern plating line, installed in 1995, has been brought up to date by the installation of the new OSSTjwin (Ordering System for Surface Treatment) software, with installation handled by PAL’s Israeli agent Tech Knowledge. “Our PAL line has been working well since its installation in 1995 and featured an earlier version of OSST, mostly on random load as we run small batches,” explains David Kishon, CTO of PCB Technologies. “We opted for the new OSSTjwin software because it enables us to run and control pulse plating without the need for additional programs or even an additional computer. “The new program has proved much more user friendly than the earlier version; our operator is able to feed and control the parameters in a much easier way. The installation ran smoothly and our operators took to the new software immediately. The line is operating well under OSSTjwin and fulfiling our expectations. We are delighted we took the step we did!” Prior to the installation, an engineer from Tech Knowledge went to Hong Kong for a one week comprehensive training session on the installation and operation of the OSSTjwin system. On his return to Israel he started the installation on site, with support from Hong Kong and Sweden via telephone and emails. The installation was completed in just a few days, with minimum interruption to the production of PCB Technologies. PCB Technologies provides an array of contract electronic manufacturing (CEM) services aimed at system manufacturers primarily in Israel and the United States. Maintaining bare-boardmanufacturing and board assembly facilities, the company focuses on the production of multi layer boards, rigid and rigid-flex boards with micro-via ability, as well as complete board assemblies. “We are very much a one-stop-shop for CEM services offering everything from design to complete production and full turnkey capabilities,” says David Kishon. “We also offer a complete line of bare and assembled board testing facilities. New product introduction (encompassing prototypes, pilots and first production runs) is handled at our headquarters in Migdal Haemek in Israel – it is this work for which the OSSTjwin system is invaluable. In order to meet high-volume production runs, our subsidiary PCB Suzhou Technologies is scheduled to be in full production later this year.” The company has a diversified customer base including system manufacturers, the telecommunications, military, space and aviation industries spread around the world – in the USA, India, South Africa and Europe. More on PCB Technologies at www.pcb.co.il

|

Retrofitting

state of the art hardware or software is proving a highly cost-effective

method of keeping installed equipment running in tune with current

customer and market needs.

Retrofitting

state of the art hardware or software is proving a highly cost-effective

method of keeping installed equipment running in tune with current

customer and market needs.