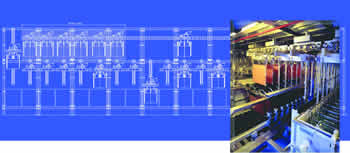

Horizontal Machines - PAL’s AnswerA three-day extensive training session was held earlier this year at Intech Machinery Co. Ltd (IML) in Taiwan with sales representatives from the USA, Europe and Hong Kong taking part. The training course covered all elements of horizontal machines from basic concepts to the latest state-of-the-art innovative designs including basic machine layout to specific configurations to meet special requirements.  PAL’s existing and well established worldwide service network ensures that the company is well prepared and ready to provide an alternative choice to the market for a complete horizontal machine comprising Desmear, PTH and Copper plating. NEW LINK WITH SIGMA ENGINEERINGSigma Engineering AB of Sweden and Process Automation International Ltd (PAL) have signed an agreement enabling PAL to act as exclusive distributor for Sigma’s Mecer Etchant Regneration Systems and Modumatic ED-Photoresist Coating Technology throughout Asia and in the UK and Ireland. “We will take over all responsibility for sales and service of Mecer equipment and ED-Photoresist Coating Technology as well as supplying spare parts and consumables to customers in those countries,” explains PAL’s Managing Director, Geoff Paterson. “There is very definite synergy between the environmental aims of our two companies and we look forward to working closely with Sigma. The Mecer process will undoubtedly meet the needs of our customers eager to conform to ever-stricter environmental rules and guidelines; and the fully automated vertical Modumatic ED-Photo Resist Coating technology, for the upcoming U-HDI technology, adds a new and strong string to our corporate bow.” The Sigma Group of Karlstad, in central southern Sweden, comprises Sigma Holmstrands AB and Sigma Metallextraction AB. “It is Sigma Metallextraction AB that has developed, designed and patented the Mecer process for on-site recycling of ammoniacal etchants used in the manufacture of printed circuit boards,” explains Sigma’s Director of Technology, Walter G Hertlein. “Our process eliminates the necessity for shipping hazardous spent etchant and offers a number of very definite economic, ecologic and technological benefits. Consumption of replenisher is eliminated, water and waste treatment costs are reduced, and the end product is competitively priced saleable electrolytic Copper panels (99.999% Cu). The Mecer system also offers greatly improved control over the etching process. We are delighted to be working with PAL in key areas of the world where there is a growing environmental commitment.” Over a hundred Mecer units have been designed and installed worldwide.  He feels just as strongly about the Modumatic ED-Photo Resist Coating Plant. This enables the realisation of structures down to 25µm linewidth and finer, 3D-products and landless designs with better yields than alternative technologies. Metallised via and blind holes are well protected during the wet process and this proven technology has demonstrated automatic handling of 50µm core material. Production units are available ranging in capability from 20 to 22 panels per hour.

|

Smaller units can be supplied with different degrees of automation

for handling panels and chemistry. Sigma has also established an

enviable track record for the supply a range of horizontal equipment

such as developers, etchers, strippers and cleaners built in stainless

steel, titanium or plastic – all are now available to PAL customers in

Asia, the UK and Ireland thanks to the deal struck between PAL and

Sigma. Further information is available from PAL offices in Asia and

the UK and via

Smaller units can be supplied with different degrees of automation

for handling panels and chemistry. Sigma has also established an

enviable track record for the supply a range of horizontal equipment

such as developers, etchers, strippers and cleaners built in stainless

steel, titanium or plastic – all are now available to PAL customers in

Asia, the UK and Ireland thanks to the deal struck between PAL and

Sigma. Further information is available from PAL offices in Asia and

the UK and via